Specification:

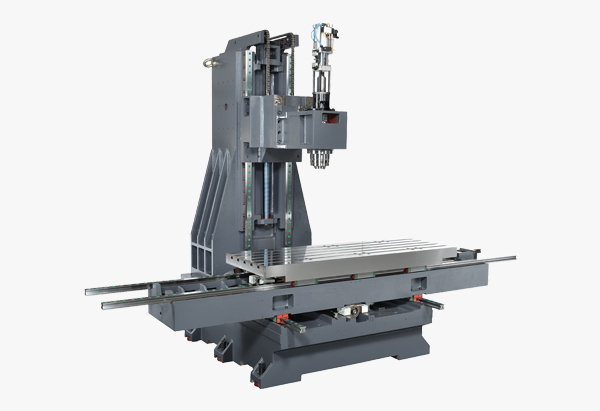

- Heavily built machine structure ensures maximum operating stability and even load distribution with machining accuracy not affected by the foundation or leveling variation.

- Primary parts are made of Meehanite cast iron, which offers high tensile strength, excellent wear resistance and longer service life.

- Slideways on 3 axes are box way designed, hardened and precision ground.

- Finely scraped guide-way surfaces are coated with Turcite-B, which ensures maximum machining accuracy and prolonged service life.

- Counter-balanced Z-axis to achieves highly smooth movement in rapid traverse and normal feed.

- To eliminate backlash, double nuts ball screws and drive servo motors are utilized on three axes.

- Counter-balanced Z-axis to achieves highly smooth movement in rapid traverse and normal feed.

- To eliminate backlash, double nuts ball screws and drive servo motors are utilized on three axes.

- Coolant and chips are kept thoroughly away from slideways for longer machine service life.(optional)

- Oil and fluid are recycled separately to have dry and clean area.

| ITEM | UNITS | YMC-650L | YMC-760L | YMC-1060L | YMC-1568L |

|---|---|---|---|---|---|

| Table | |||||

| Size | mm | 770 x 400 | 1000 x 410 | 1300 x 520 | 1700 x 600 |

| T-slot | mm x T | 3-18T x 125 | 3-18T x 125 | 18mm x 5 | 18mm x 5 |

| Max table loading | Kgs | 400 | 700 | 1000 | 1500 |

| Travel | |||||

| X, Y, Z axis | mm | 650 / 410 / 500 | 760 / 410 / 660 | 1000 / 600 / 700 | 1500 / 760 / 880 |

| Spindle nose to table | mm | 100-600 | 100-760 | 100-810 | 100-980 |

| X, Y, Z ballscrew | mm | Ø40-P10 | Ø40-P10 | Ø40-P10 | Ø40-P10 |

| X, Y, Z linear guideway | mm | Roller | Roller | Roller | Roller |

| X Y Z N °linear guideway | mm | 2, 2, 2 | 2, 2, 2 | 2, 2, 2 | 2, 2, 2 |

| XYZ block of guideway | mm | 4, 4, 4 | 4, 4, 4 | 4, 4, 4 | 4, 4, 4 |

| Spindle | |||||

| Type | Belt / Optional change to direct | ||||

| Taper | 40 | 40 | 40 | 40 | |

| Diameter | mm | Ø70 | Ø70 | Ø70 | Ø70 |

| Speed | mm | 8000 / Option 10000 / 12000 | 8000 / Option 10000 / 12000 | ||

| Feed | |||||

| Three axes | Linear guideway (Roller type) | Linear guideway (Roller type) | |||

| Cutting feedrate | m/min | 10 | 10 | 10 | 10 |

| Rapid feedrate | m/min | 36 / 36 / 30 | 36 / 36 / 30 | 36 / 36 / 30 | 36 / 36 / 30 |

| ATC | |||||

| Tool selection | rpm | Auto / Random | Auto / Random | ||

| Max tool dia | mm | Ø 130 / Ø 125 | Ø 130 / Ø 125 | ||

| Max tool length | mm | 350 / 350 | 350 / 350 | ||

| Max tool weight | Kgs | 8 / 8 | 8 / 8 | ||

| ATC type | ARM less 20T / Optional:ARM type 24T | ARM less 20T / Optional:ARM type 24T | |||

| Motors | |||||

| Spindle motor. | HP | 7.5 | 7.5 | 7.5 | 7.5 |

| X, Y, Z motor | 2, 2, 2 | 2, 2, 2 | 2, 2, 3 | 2, 2, 3 | |

| Other | |||||

| Machine packing | cm | 225 x 228 x 255 | 225 x 228 x 255 | 330 x 228 x 255 | 420 x 228 x 255 |

| Machine weight | Kgs | 4000 | 4200 | 6500 | 7000 |

| Machine dimensions | cm | 261 x 210 x 243 | 261 x 210 x 243 | 387 x 257 x 292 | 478 x 259 x 323 |

- ARMLESS TYPE ATC 20 TOOLS

- FULL SPLASH COVER

- SCREW TYPE CHIP CONVEYOR

- POWERFUL CHIP FLUSH NOZZLE

- COOLANT WATER UNIT

- AUTO LUBE SYSTEM

- SPINDLE AIR BLAST

- WORK LIGHT

- ALARM LIGHT

- HEAT EXCHANGER

- TOOL BOX

- WORK LAMP

- SPINDLE OIL COOLER

- POWER SOURCE TRANSFORMER

- ARM TYPE ATC 24 TOOLS

- COOLANT THROUGH SPINDLE

- 10000/12000 RPM SPINDLE

- GERMANY ZF GEAR SPINDLE

- 4TH AXIS & 5TH AXIS ROTARY TABLE & TILTING HEAD

- BELT TYPE CHIP CONVEYOR

- CE STANDARDS