Specification:

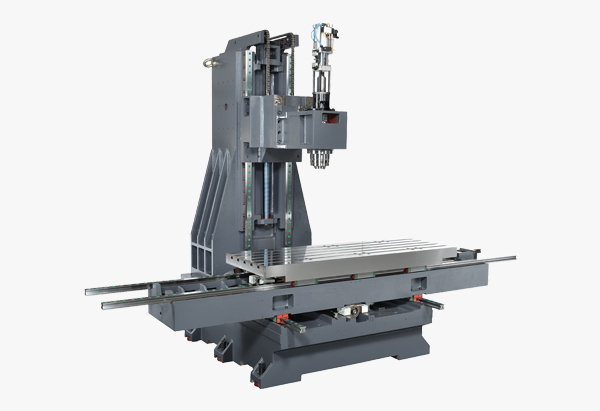

Built With High Rigidity

- Heavily built machine structure ensures maximum operating stability and even load distribution with machimimg accuracy not affected by the foundation or leveling variation.

- Primary part are made of Meehanite cast iron, which offers high tensile strength, excellent wear resistance and longer service life.

- Slideways on 3 axes are box way designed, hardened and precision ground.

- Finely scraped guide-way surfaces are coated with turcite-B, which ensures maximum machining accuracy and prolonged service life.

- Counterbalanced Z-axis achieves highly smooth movement in rapid traverse and normal feed.

- To eliminate backlash, double nut ball screws and servo motor drive are utilized on three axes.

- Collant and chips are kept thoroughly away from slideways for longer machine service life.

- Oil and fluid are recycled separately to have a dry and clean work area.

- The spindle runs on P4 class precise angular contact ball bearing (Front: 4 pcs & Rear: 2 pcs) made of high quality alloy steel, heat- treated and precision ground for long running time and constant temperature at high speed.

- The spindle is lubricated by special oil and circularly cooled by coolant through spindle motor that generates minimum heat and ensures precision and stability with constant temperature in high-speed machining and heavy-duty cutting.

- The spindle nose combined air blow to prevent coolant or chips from contamination. It also ensures spindle accuracy and its service life.

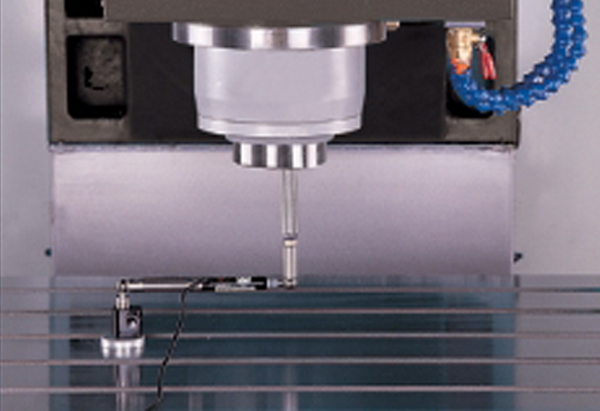

High Precision, High Rigidity Spindle

- The spindle runs on P4 class precise angular contact ball bearing(Front: 4pcs & Rear: 2pcs) made go high quality alloy steel, heat-treated and precision ground for long running time and constant temperature at high speed.

- The spindle is lubricated by special oil and circularly cooled by coolant through spindle motor that generates minimum heat and ensures precision and stability with constant temperature in high-speed machining and heavy-duty cutting.

- The spindle nose combined air blow to prevent coolant or chips from contamination. It also ensures spindle accuracy and its service life.

YMC-2085

- Full guarding with screw chip conveyor and back ward flushing

- Full enclosure

- Box way/direct

- Telescopic covers on 3 axes total 5 set

- Arm less 20 tools/arm type 24 tools (random)

- Warlus coolant system

- Rigid tapping

- Auto lubrication

- Working light and 3 color alarm light

- MPG

- New design 2 meter machine. Without full container, save space

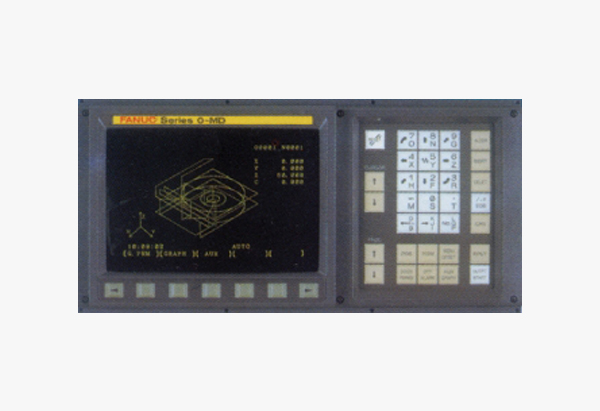

- Mitsubishi M70/FANUC OI-MD/SIEMENS 828D

- Testing reports

- Machine manual and parts list

YMC-1050 / YMC-1060 / YMC-1368 / YMC-1568 Specification

| ITEM | UNITS | YMC-1050 | YMC-1060 | YMC-1368 | YMC-1568 |

|---|---|---|---|---|---|

| Movenment | |||||

| X-Axis Travel | mm | 1000 | 1000 | 1300 | 1524 |

| inch | 39.4" | 39.4" | 51.2" | 60" | |

| Y-Axis Travel | mm | 500 | 600 | 720 | 720 |

| inch | 19.7" | 23.6" | 26.8" | 30" | |

| Z-Axis Travel | mm | 570 | 570 | 670 | 670 |

| inch | 22.4" | 22.4" | 22.4" | 22.4" | |

| Spindle Nose to Table | mm | 100 ~ 670 | 100 ~ 670 | 100 ~ 770 | 100 ~ 770 |

| Spindle Center to Column surface | mm | 600 | 600 | 700 | 700 |

| Ball Screw | |||||

| Pitch | mm | Ø10 | |||

| X Axis | mm | Ø40 | |||

| Y Axis | mm | Ø40 | |||

| Z Axis | mm | Ø40 | |||

| Feed Rate | |||||

| X, Y, Z-Axes Rapid Traverse | m/min | 15 | 15 | 15 | 15 |

| Diameter | m/min | 5 | 5 | 5 | 5 |

| Table | |||||

| Table Size | mm | 1200 x 500 | 1300 x 600 | 1700 x 600 | 1700 x 600 |

| inch | 47.2" x 19.7" | 51.2" x 23.6" | 66.9" x 23.6" | 66.9" x 23.6" | |

| Max. Loading Capacity | kgs | 800 | 800 | 1000 | 1000 |

| ibs | 1760 | 1760 | 2200 | 2200 | |

| Number of T-slots | 5 | 5 | 5 | 5 | |

| Size of T-Slots | mm | 16 | 18 | 18 | 18 |

| Headstock | |||||

| Spindle Speed | rpm | 60 ~ 8000 | |||

| rpm | Optional: 10000, 12000 | ||||

| Spindle Diameter | mm | 70 | |||

| Spindle Taper | BT-40 /CAT-40 | ||||

| Maximum Tool Diameter | mm | 100 | |||

| Tool Storage Capacity | Tools | Armless ATC 20 | |||

| Optional: Arm Type ATC 24 | |||||

| Coolant Pump | HP | 1/2 | 1/2 | 1/2 | 1/2 |

| Air Pressure | kg/cm2 | 5 | 5 | 5 | 5 |

| Spindle Motor | HP | 10 | 10 | 15 | 15 |

| Machine Weight | kgs | 5000 | 5500 | 6200 | 6600 |

| lbs | 11000 | 12100 | 13640 | 14520 | |

| MODEL | UNITS | YMC-2085 |

|---|---|---|

| Type | BoxWay | |

| Table size | mm | 2100 x 762 |

| XYZ Travel | mm | 2000 / 850 / 800 |

| Spindle Nose to Table | mm | 100 - 900 |

| Spindle Motor | kw | 11 / 15 |

| Ballscrew Size | Double Nut | Ø50-P10 |

| Tabld Max Loading | kgs | 1800 |

| T-slot | mm | 5 x 18 |

| Spindle | BT / CAT / DIN | #40 |

| Spindle Speed | rpm | 8000 / 10000 |

| ATC | Arm Less 20T / Arm Type 24T | |

| XYZ Rapid Travel Rate | m/min | 30 / 30 / 24 |

| XYZ Cutting Feed Rate | m/min | 20 |

| Machine size | cm | 410 x 28 x 255 / 180 x 228 x 250 |

| Machine Weight | kgs | 8800 / 9400 |

- ARMLESS TYPE ATC 20 TOOLS

- FULL SPLASH COVER

- SCREW TYPE CHIP CONVEYOR

- POWERFUL CHIP FLUSH NOZZLE

- COOLANT WATER UNIT

- AUTO LUBE SYSTEM

- SPINDLE AIR BLAST

- WORK LIGHT

- ALARM LIGHT

- HEAT EXCHANGER

- TOOL BOX

- WORK LAMP

- SPINDLE OIL COOLER

- POWER SOURCE TRANSFORMER

- ARM TYPE ATC 24 TOOLS

- COOLANT THROUGH SPINDLE

- 10000/12000 RPM SPINDLE

- GERMANY ZF GEAR SPINDLE

- 4TH AXIS & 5TH AXIS ROTARY TABLE & TILTING HEAD

- BELT TYPE CHIP CONVEYOR

- CE STANDARDS